Applications

Active natural molecules (secondary metabolites)

Secondary metabolites (such as stilbenes and alkaloids) are traditionally extracted from plants grown in fields or greenhouses. Factors like environmental variability can adversely affect yields.

Samabriva’s technology enables the production of secondary plant metabolites with greater efficiency, consistency, and purity while reducing the environmental impact.

Our bioproduction system is a more sustainable, cost-effective way to make biomolecules all year round, in any location without complex supply chains.

Current system

- 1. Grown in open fields in competition with food crops

- 2. Large footprint

- 3. Geopolitical risks

- 4. Seasonality

- 5. Long production cycle

- 6. Climate change risk

- 7. High carbon footprint (from farming and transport) and associated cost

- 8. Low molecule content per kilogram of plant

Samabriva’s process

- 1. Contained and controlled production

- 2. Compact footprint

- 3. Control of the supply chain

- 4. Year-round continuous production

- 5. No climate risk for greater batch-to-batch consistency

- 6. Low carbon footprint (no light, heat or transport)

- 7. Higher yield of desired molecule per kilogram of plant material

- 8. Cost-effective purification

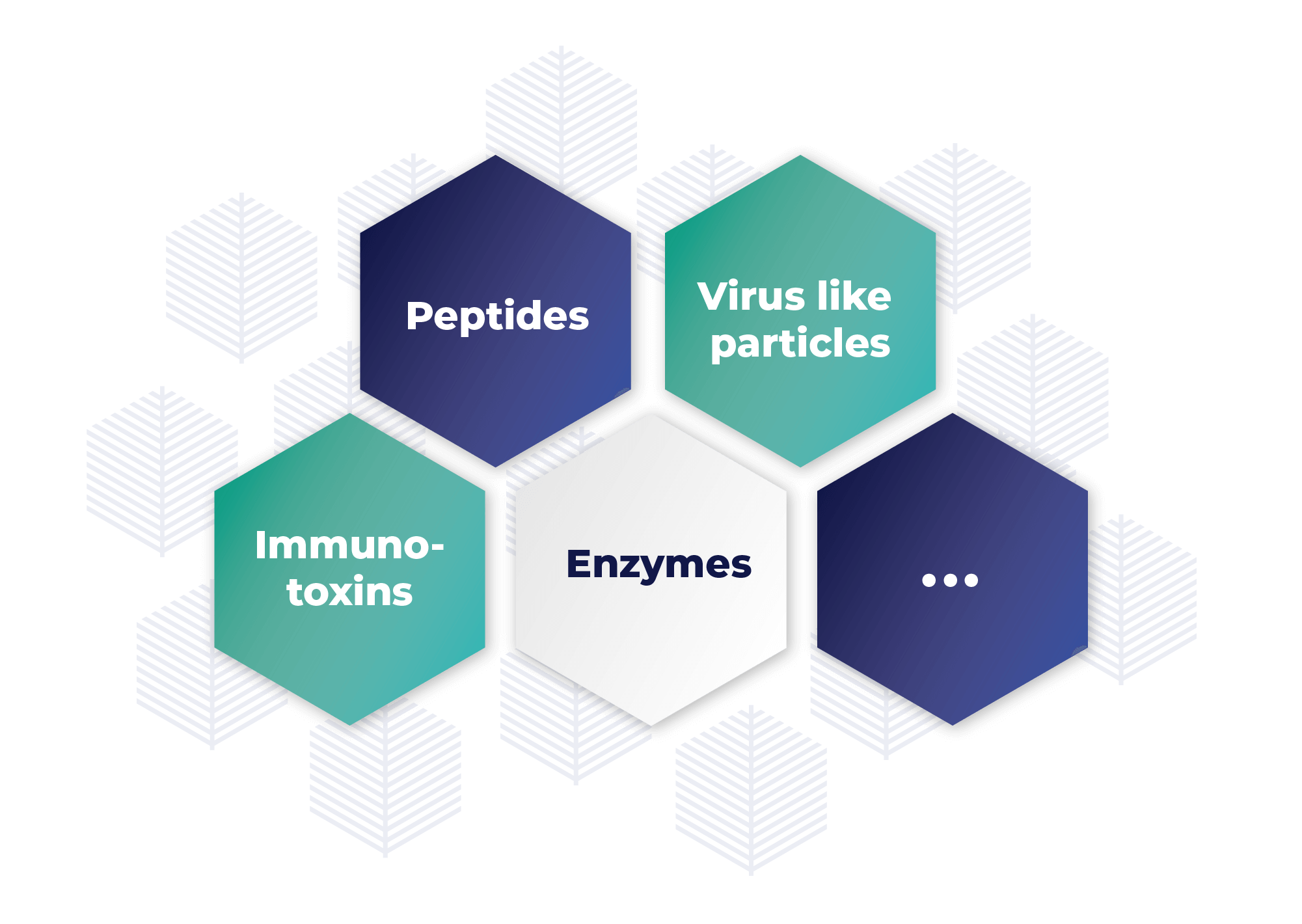

Recombinant proteins

Our hairy root system offers a lower CAPEX and COGS solution for producing recombinant proteins. The process delivers superior protein production with all the benefits of eukaryotic cell culture: precise folding, enhanced stability and consistent results.

The process is similar to traditional cell line cultures as it allows us to seamlessly apply regulatory guidelines such as confinement measures, the use of Master and Working “Root” Banks, and in-process controls to ensure the quality and safety of the final product.

Robust and highly flexible platform easily transferable anywhere in the world.

KEY BENEFITS

Low CAPEX and COGS

Cost reduced by 50-70% compared with CHO

Stable production process

Over 97% liter retention with <3% growth rate variation after 70+ sub-cultures

Straightforward technology

Plug-and-play process that’s easily transferable worldwide

Scalable

Horizontal and vertical scale-up in line with GMP requirements

Highly productive

1,5g/L for recombinant proteins

Animal component free

Proteins produced from an edible plant with no risk of animal virus contamination

Simplified purification (DSP)

Secretion of protein product into the media

Positive feedback

From the French regulatory agency (ANSM)